June in my home state of Oklahoma is typically hot and dry, and the prospect of doing any flyfishing for trout just isn’t a consideration unless I want to drive four hours or so to make it happen. So, you can imagine my quick change in mood when the editor of Hook & Barrel called me on a 90-degree day and asked if I wanted to go to northwest Idaho to tour the Buck Knives factory and test a fly rod and reel.

Of course, he had me at the Buck Knives factory tour, as I’ve been a huge fan ever since I was a young child growing up in rural Oklahoma.

I can still remember standing at the TG&Y store in south Oklahoma City, barely tall enough to peer into the glass-topped knife display, wishing that I was old enough — and that I had enough money — to buy one of those beautiful Buck 110 Folding Hunters that were all the rage at the time.

With Buck Knives on the agenda and trout fishing to seal the deal, all I could say was, “Sign me up for this field trip!”

A Buck Knives History Lesson

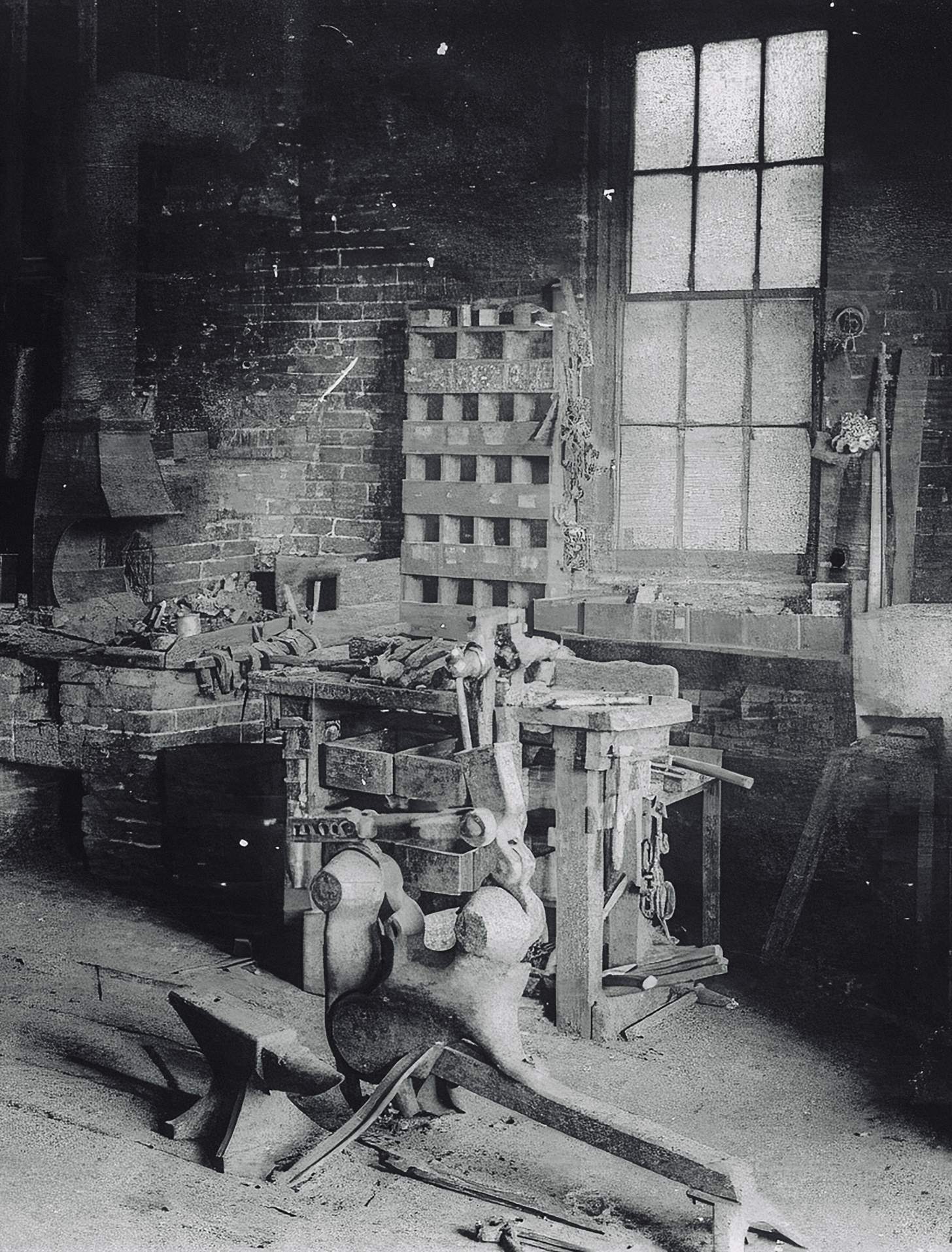

Nearly 125 years ago, a young blacksmith apprentice from Kansas, Hoyt Buck, was dissatisfied with how steel was tempered to maintain a lasting edge.

Looking for a better way to keep a blade sharp, Hoyt’s innovative method led to the creation of the first Buck Knife in 1902. Using worn-out file blades as raw material, Hoyt handcrafted each knife — a demanding process that yielded excellent results.

Later, during World War II, Hoyt’s oldest son, Al Buck, had just finished a stint in the Navy and moved to San Diego. Thinking that the grass might be greener out west, Hoyt and his wife, Daisy, relocated to San Diego in 1945 and started H.H. Buck & Son. The custom knife business led to the Buck family founding Buck Knives Inc. in 1961.

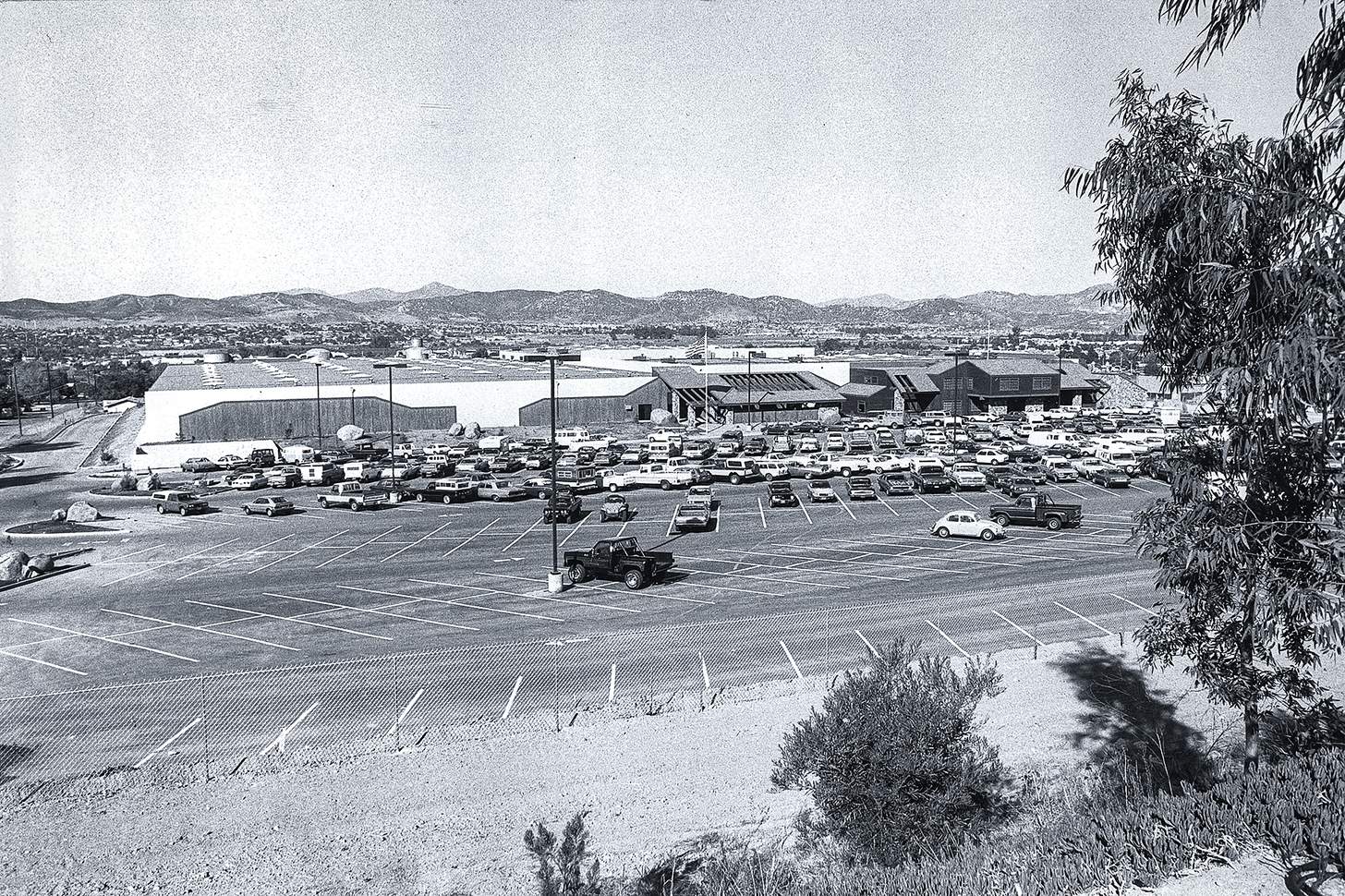

Business thrived in California for nearly 60 years as Buck Knives built a reputation for quality and durability. However, the company faced several economic challenges and, in 2005, moved to Post Falls, Idaho, just outside Coeur d’Alene.

Committed to manufacturing in the United States and continuing to produce innovative products, the relocation was a necessary step for Buck to ensure its future success.

The area, incidentally, is the ideal location for Buck Knives. The Pacific Northwest boasts abundant hunting, fishing, hiking, camping, and other outdoor activities, along with a supportive community that has played a key role in the company’s success.

With the capacity to produce thousands of knives each day, Buck proudly employs over 300 workers at its Idaho facility, all dedicated to quality and dependability. And notably, every one of the company’s knives is made right here in the USA.

Buck Knives Factory Tour

When our van pulled up to the Buck factory in Post Falls, the anticipation was clear. Here we were visiting a knife-making legacy that had been in the business for twice as long as many of us had been alive.

A quick visit to the small museum, with a glass window overlooking the factory floor, was a great start. There, we saw several historic knives, from the first few made by Mr. Buck in the early 1900s to others that had been removed from the inventory years ago. A pictorial timeline told the story of the Buck family, and decades of knives filled the display cases.

During a short briefing, we learned how Buck Knives had adapted to challenges over the years.

To fulfill its vision of being the Number 1 preferred hunting knife brand and top-three brand for everyday carry, the company adopted a new business model based on lean cellular manufacturing, recruiting a highly motivated workforce and putting together a consolidated outside sales force.

So far, the strategy has worked well, with the company achieving record-high sales the past few years.

A knife factory is a noisy environment, so after putting on eye and ear protection, we headed inside. I quickly realized there’s a lot involved in making top-quality knives, but the most crucial part is the skilled craftsmen who have been working there for years and still take great pride in their work every day.

The heat-treating area was especially fascinating. Did you know that Buck Knives is so renowned for its heat treating that it even heat treats blades for several custom knife makers?

In the late 1970s, Paul Boss, the pioneer of heat treating, helped Buck establish its own heat treating department, complete with ovens and all the necessary equipment.

By heating and then cooling blades, Buck can alter the physical and structural properties of the blade metal to achieve the desired hardness, along with other qualities.

One of the most recognizable Bucks to most hunters is the Model 119 fixed blade, which the company has been making since 1942.

During the tour, we were all handed a 119 fresh off the factory floor and given the chance to put the initial edge on the knife, then take it home to see how it cuts.

I botched mine so badly it looked like a 4-year-old did it, but when nobody was looking, I had one of the professionals put a factory edge on it.

What’s New At Buck Knives

Of course, Buck still produces the legendary 110 Folding Hunter, its most popular knife ever. But Buck has also evolved with the times, recently launching its new Range Series, which includes the 791 Range Pro (3.375-inch blade), 791 Range Elite (3.375), 790 Mini Range Pro (2.625) and 790 Mini Range Elite (2.625).

These are high-end folding knives designed for whatever daily task you might face.

Besides the premium steel (the MagnaCut blade maintains its edge through tough jobs, meaning less sharpening and more cutting), another interesting feature on these new models is the crossbar locking mechanism.

This allows the user to close the knife without getting fingers in the way—a bonus considering how sharp these knives come straight from the factory. All have a thumb stud opener for effortless one-handed operation, along with a tough, lightweight aluminum handle and ambidextrous pocket clip.

Those of us lucky enough to be on the factory tour later had the chance to build our own 791 Range Elite. First, let me say that assembling one from a bag of parts isn’t very complicated.

However, considering how long it took me to put mine together, if I were doing it on the Buck assembly line, they’d definitely struggle to turn a profit. The finished product, though, is a knife that anyone would be proud to own.

I’ve carried mine daily since I came back from the Idaho trip, and I’ve used it for everything—from cutting feed sacks and a leather girth strap to a T-bone steak. There’s no doubt it will also perform well in the deer woods if I decide to use it there.

How Buck Knives Will Be Cutting Into The Future

Ultimately, the future of this legendary knife company looks very promising. While Buck still produces its avorites like the 110 Folding Hunter and the 119, it has also embraced the future with its exceptional newer models.

Now under the leadership of CJ Buck, the fourth generation of the Buck family knives dynasty, the company continues to uphold its three core pillars—legacy, authenticity and craftsmanship.

As long as it stays true to these principles, there’s little doubt that the company will remain a leader in the blade industry for decades to come.

Best Buck Knives for Every Season

Buck Knives offers a wide range of well-made knives that are very useful for specific tasks. Here’s a look at my top picks for each season. Sure, many knives can serve multiple purposes, but what’s the fun in only having one knife!

Deer and Big Game

For all the chores you might have in the deer woods, there’s still no other Buck like the Model 119. This fixed-blade hunting knife features a large, hand-sharpened clip blade with a broader cutting surface at the belly.

The aluminum guard at the base of the blade provides protection for your hand, and the knife is finished with an aluminum pommel for a timeless look.

Fishing

Yes, Buck makes fishing knives. The model 220 Silver Creek Folding Fillet Knife handles everything you need for cleaning fish and folds into a compact 7.25-inch length.

It features a flexible, titanium-coated 420J2 steel blade, a rubberized anti-slip grip and a stainless steel safety guard. The total weight is just 6 ounces, and a convenient lanyard hole makes carrying easy.

Skinner

The Buck 103 Skinner Knife, introduced in 1961, features a 4-inch 420HC steel skinner blade and a phenolic handle. The blade’s tip is narrow, while the curved belly helps in cutting through thick layers.

The overall length is 8.25 inches, and it weighs only 4.3 ounces. The 103 comes with a black, genuine leather carry sheath.

Everyday Carry

For an everyday carry blade, I’d choose the new 790 Mini Range Elite. Its MagnaCut blade stays sharp longer, and the lightweight aluminum handle makes it easy to slip into your pocket.

Its 2.625-inch blade is .75 inches shorter than the 791 Range Elite I carry daily, creating a little more room in your pocket for other essentials.