In January 2025, Bob Brown was appointed president of Yamaha Motor Manufacturing Corporation in Newnan, Georgia. I think we can credit our access to the company's facility there to Brown directly. It would have been a rare thing in the past to allow outsiders with cameras on the assembly line floor of the Yamaha factory, but I think Brown feels that it is important to show Hook & Barrel readers just how committed YMMC is to making the best products for consumers.

During our exclusive, behind-the-scenes tour (see video above), there were still a few places that we couldn’t see, top secret torture testing and new product R&D for example. But it was still pretty awesome to see how the sausage is made, especially since these particular sausages are high-powered four-wheel-drive terrain-rippin’ ATVs and side-by-sides.

Once through security, we made our way to the assembly line floor. Forklifts flashed past at speed, honking at regular intervals, as we made our way around the outer wall of the facility, following the yellow safety lane meant to keep pedestrian foot traffic from getting smooshed.

The assembly line follows a “U” shape. We emerged at the bend, walking to the left to where the “start” of the line exists somewhere down the vanishing point.

Horns, sirens, air tools and other machinery created a mechanical symphony. Before we stepped out from the safety corridor, we made sure to look left and right for forklifts like good little tourists.

The Vibe On The Yamaha Production Line

Every Yamaha Waverunner, Golf Cart, side-by-side ROV, and the majority of the ATVs in the world are assembled at the Newnan, Georgia facility.

While on site, we focused mainly on ATVs, specifically the Grizzly utility series. And as luck would have it, a fresh set of Grizzly EPS XT-R models (see below for full specs) were just starting to emerge around the corner of the assembly line.

The line is set up in stages: A frame is loaded on a hanging cart. As the carts move down the line, workers install the steering, liquid-cooled 686cc engine, wiring harness, winch, axles, radiator, fluids, four-wheel hydraulic disc brakes, lights, moulded plastic, tires, etc.

From bare frame to a complete unit involves around 170 employees, and takes about an hour.

As far as I could tell this particular line handled ATVs and golf carts, and that meant the line had to be able to effectively get all the correct parts and fasteners for 400 different variations to each station when the line switched, which happened multiple times per day. The army of forklifts now makes sense.

Once completed, an ATV is removed from the line, started, and tested on a dyno for power and function. This is accomplished by applying power while positioned on large steel rollers in a controlled setting, ensuring proper function for every unit that comes off the line.

Once that is done, the unit is loaded on carts, ready for shipping. I overheard that the Grizzly ATVs we saw were eventually headed to Canada, eh.

Yamaha Wolverines! Side-By-Side Assembly

We left the ATV line, and headed out through the 1.3 million square feet of manufacturing space to find the side-by-side assembly line. We passed racks and crates stacked with countless parts — raw fiberglass shells stacked to the ceiling — through the mechanical clank and hum of manufacturing until eventually I heard the buzz of welding.

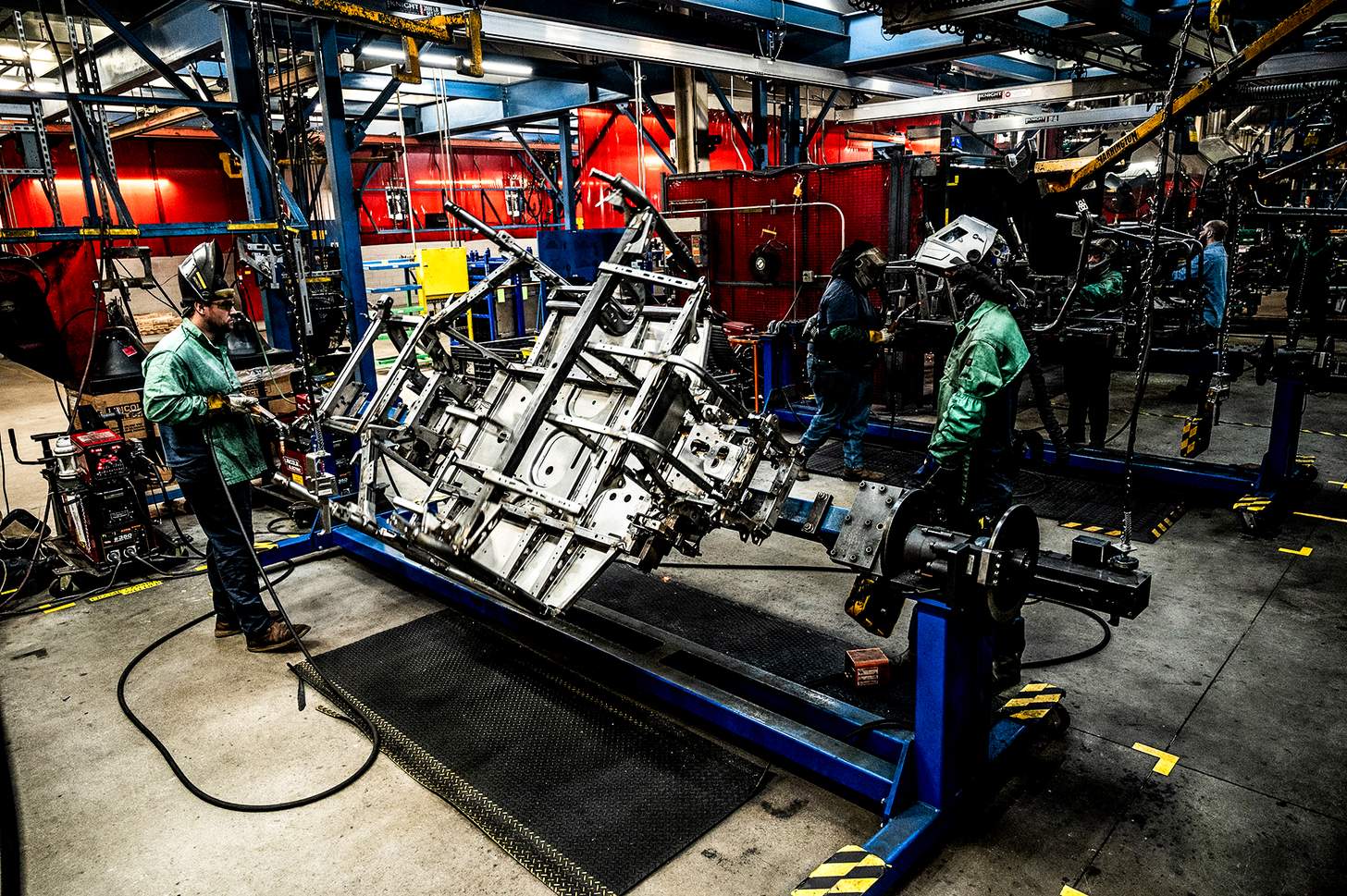

An aisle of CNC machines held tubing and sheet metal pieces in precision jigs, and workers stood around large rotating tables, hand-welding components too large or complicated for the robots to accomplish.

These raw frames then get attached to hangars to be lifted off into the ceiling, heading for washing, dipping, painting, powder coating, before finally emerging back on the assembly floor, stacked and ready for the line.

Like with the ATVs, we followed the progress of a side-by-side as it came to life. The model being assembled that day was the new 2026 Wolverine RMAX4 1000 XT-R (see below for full specs).

Instead of the frames hanging from the roller-coaster style tracks in the sky, they sat on low electric carts that slowly trudged their burdens along painted lines on the floor. Then the same process — engines, wiring, suspension, fluids, plastics, etc, then off the line into a dyno, then packed for shipping.

The whole process was basically what I was expecting, but I was awed by the scale: the mechanical ant farm, built around efficiency and economy of movement.

So many pieces, parts, wires, fittings, all delivered on time and to the correct location, into the hands of specialized professionals, performing a task in an hour that would take me and two of my most mechanically-minded friends all day.

Even as efficient as it is, there are company programs that allow employees to recommend changes or enhancements to the process, where they can submit ideas or requests that may make the process even better. I got the idea that at YMMC, a lot of effort goes into employee satisfaction.

Yamaha Product Lifecycle And Sustainability

Beyond assembly, the YMMC facility features state-of-the-art product development and testing capabilities. Yamaha’s teams in Newnan are involved in the full product lifecycle, from concept through production, involving design and engineering, prototype creation, and onsite field and durability testing.

All of this happens on the 280-acre YMMC campus in Newnan, Georgia, and ensures all Yamaha products maintain tight quality control.

For decades, YMMC has been committed to environmental and community improvement. Among other things, the facility produces a couple of million watts from solar and diverts 97% of its waste from landfills for recycling.

Yamaha then invests that money into employee benefits, the facility, and the community, turning sustainability efforts into tangible local impact.

YMMC’s community initiatives focus on several key areas, including education and youth development and leadership, STEM learning, community safety, and environmental stewardship.

One fun example of hands-on STEM learning is an involvement with the Coweta Grand Prix, a soapbox derby-style race that challenges students to design, build, and race their own gravity-powered cars.

Yamaha provides the Downhill Dreams Academy, which helps students apply STEM concepts to help bring their cars from concept to competition.

Yamaha’s Future Expansion

YMMC’s dedication to providing the best products for consumers, as well as its commitment to strengthening the community is obvious. I was told that the facility is expanding its manufacturing capabilities and plans to add the ability to laser cut and CNC more components in-house, strengthening their commitment to quality control.

There is a core philosophy at Yamaha based on the idea of “kando,” which is a Japanese term which describes a “deep satisfaction and excitement felt from encountering something extraordinary.”

They want their customers to not just be happy with the functionality of a product, but to be fulfilled and inspired. They want their customers to have an emotional connection with the products through design, value, and experience. This philosophical value is not just for the customers, but for the employees, community, and the YMMC.

Hook & Barrel would like to thank President Bob Brown and all the managers and employees who took the time to show us around, answer questions, and make the experience so great.

And special thanks to all the employees who put up with us and our cameras. Explore the full 2026 Yamaha Motorsports lineup at yamahamotorsports.com.

Yamaha ATVs Lineup — New For 2026

The 2026 Grizzly, which we saw built during our behind-the-scenes exclusive at Newnan, GA, continues to set the standard for high-performance trail-ready utility ATVs, combining big-bore power with rugged capability.

Its 686cc liquid-cooled engine delivers optimized midrange torque for technical terrain. Yamaha’s class-leading Electric Power Steering (EPS) is optimized with speed-sensitive steering assist to tackle a wide range of conditions.

Additionally, Maxxis tires, four-wheel hydraulic disc brakes, and fully independent long-travel suspension add to the Grizzly’s off-road credibility. For younger trail riders, the 2026 Grizzly 110 combines adventurous styling with confidence-inspiring performance for riders ages 10 and up.

The 2026 Kodiak 700 and 450 offer hard-working utility with a focus on value, compact handling and durability. The Kodiak 700 shares the same 686cc engine as the Grizzly tuned for smoother, low-rpm performance with a more compact chassis ideal for tight trails or job sites.

The Kodiak 450 delivers full-size capability in a mid-size platform, powered by a 421cc engine. Built-in utility includes steel cargo racks and a 2-inch receiver for cargo and towing capacity, while optional EPS elevates comfort and performance.

All of Yamaha’s full-size utility ATVs elevate Proven Off-Road capability, comfort, and confidence with the following features:

- Ultramatic CVT transmission provides immediate throttle response and natural all-wheel engine braking for confident control, backed by an industry-exclusive 10-Year Belt Warranty*.

- On-Command 4WD system gives riders the ability to choose between 2WD, limited-slip 4WD or fully locked 4WD at the push of a button.

- Independent double wishbone suspension helps maintain stability and ride comfort across uneven terrain.

The 2026 Yamaha utility ATV lineup is available in the following trim levels:

- 2026 Grizzly in Tactical Green / Acid Green.

- 2026 Grizzly CAMO in Realtree Edge.

- 2026 Grizzly XT-R in Moss Grey / Tactical Black.

- 2026 Grizzly 110 in Armor Grey or Tactical Green / Acid Green.

- 2026 Kodiak 700 in Tactical Green with optional EPS.

- 2026 Kodiak 700 EPS CAMO in Realtree Edge.

- 2026 Kodiak 700 EPS XT-R in Moss Grey / Tactical Black.

- 2026 Kodiak 450 in Steel Blue or Tactical Green with optional EPS.

- 2026 Kodiak 450 XT-R in Moss Grey / Tactical Black.

- 2026 Kodiak 450 EPS CAMO in Realtree Edge.

Specifications 2026 Grizzly EPS XT-R

ENGINE

- 686cc liquid-cooled SOHC 4-stroke

- Compression Ratio 10.0:1

- Yamaha Fuel Injection (YFI), 44mm

- Ultramatic V-belt with all-wheel engine braking; H, L, N, R, P

- On-Command 3-way locking differential; 2WD, 4WD, locked 4WD; shaft

- Fuel Capacity 4.8 gallons

CHASSIS

- Independent double wishbone; 5-way preload adjustment, 7.6-in travel

- Independent double wishbone with anti-sway bar; 5-way preload adjustment, 9.1-in travel

- Brakes/Front Dual hydraulic disc

- Brakes/Rear Dual hydraulic disc

- AT27 x 10-14 Maxxis 'Zilla MU01

DIMENSIONS

- LxWxH 81.5 in x 49.2 x 50 inches

- Seat Height 36.6 inches

- Wheelbase 49.2 inches

- Max. Ground Clearance 11.8 inches

- Fuel Capacity 4.8 gallons

- Wet Weight*** 783 pounds

- Warranty 6 Month (Limited Factory Warranty) - 10-Year V-Belt Limited Warranty

Specifications 2026 Wolverine RMAX 1000 XT-R

ENGINE

- 999cc liquid cooled, 4-stroke, DOHC, 4-valve, 108HP

- Compression Ratio 11.2:1

- Yamaha Fuel Injection (YFI); dual 48mm throttle bodies

- Ultramatic V-belt with all-wheel engine braking; L, H, N, R

- On-Command 4-way locking differential; Turf Mode, 2WD, 4WD, full diff-lock 4WD

- Fuel Capacity: 9.2 gallons

CHASSIS

- Independent double wishbone with anti-sway bar, FOX QS3 piggyback shocks; 14.2-in travel

- Independent double wishbone, FOX QS3 piggyback shocks; 16.9-in travel

- Brakes/Front Dual hydraulic disc

- Brakes/Rea- Dual hydraulic disc

- Tires/Front 30 x 10.00R-14 Maxxis Carnivore

- Tires/Rear 30 x 10.00R-14 Maxxis Carnivore

DIMENSIONS

- Stance Width 64 inches

- LxWxH 119.3 in x 66.1 x 77.8 inches

- Wheelbase 86.7 inches

- Max. Ground Clearance 13.8 inches

- Fuel Capacity 9.2 gallons

- Wet Weight*** 1,993 pounds

- Warranty 6 Month (Limited Factory Warranty) - Yamaha 10-Year Belt Warranty

For more on the 2026 Yamaha Side-by-sides lineup, check out H&B’s Yamaha 2026 Unveiling post.